Manufacturing Facilities

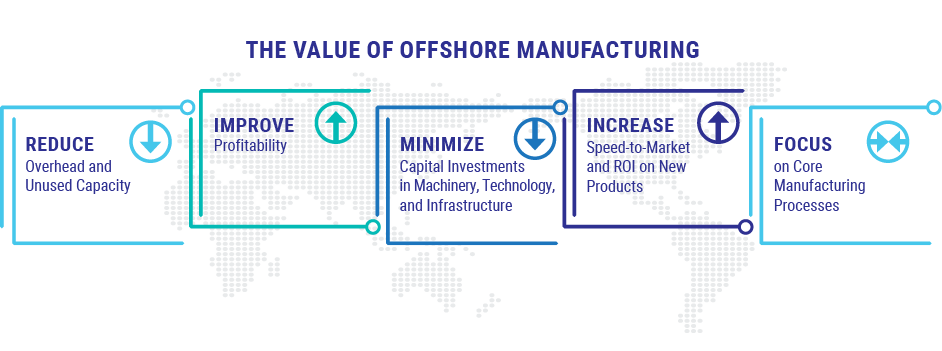

BTX can meet the offshore manufacturing and logistics needs of small to large companies in virtually any industry. We invest in carefully selected factories and maintain a global network of partnerships with trusted suppliers and subcontractors. Every supplier and subcontractor in our network adheres to the highest practices and standards established by BTX to minimize risk, maximize quality, reduce production time and ensure reliable delivery schedules.

We have developed a proprietary audit process to evaluate and approve any new supplier that we admit to our network. Every supplier in our network must also pass an annual audit to ensure they continue to adhere to our GMP standards and meet all established labor requirements. This provides our clients with the peace of mind that their products are made in accordance with all established industry guidelines.

Our core design, manufacturing, and assembly capabilities include:

Precision Metal Fabrication

Precision Metal Fabrication

- – CNC

- – Castings

- – Extrusions

- – Stamping

Injection molding

Injection molding

- – Plastic

- – Metals

Textiles – Fabrication and Conversion

Textiles – Fabrication and Conversion

- – Synthetic and Natural Fabrics

- – Woven and Non-woven materials

- – FR compliant fabrics

- – Protective Apparel for Industrial, Safety and Food Processing Environments

Wood Products

Wood Products

- – FSC compliant products

- – Food grade woodenware

- – Multi-purpose poles, dowels and handles

Custom Tooling, Molds and Packaging

Custom Tooling, Molds and Packaging

Our approach to business is 100% customer-centric.

BTX works closely with clients to identify and develop items that are more competitively produced offshore. Our efforts augment but don’t replace–existing domestic manufacturing operations.